Beijing TransFar Electronics Group Co., Ltd

Beijing TransFar Electronics Group Co., Ltd

(R Series)

R-type transformer is a rookie in dry-type transformer products. The iron core is made of high-quality oriented cold-rolled silicon steel strips of different widths and rolled into a round waist, and the cross-section is round, so it can be wound without cutting. Therefore, the transformer thus manufactured has no noise, small flux leakage, small no-load current, low iron loss, and high efficiency; and because the coil is cylindrical, the length of copper wire per turn is short, so the internal resistance is small and the copper loss is low. , low temperature rise, small overload fluctuation, and better explosive power than toroidal transformers; in addition, the primary and secondary coils are wound separately with skeletons made of flame-retardant PBT engineering plastics, so that they have high electrical strength and good flame retardancy. R-type transformers are being favored by more and more electronic industries with their novel and unique structure and excellent electromagnetic properties. Especially suitable for medical equipment, display equipment, audio equipment, office equipment.

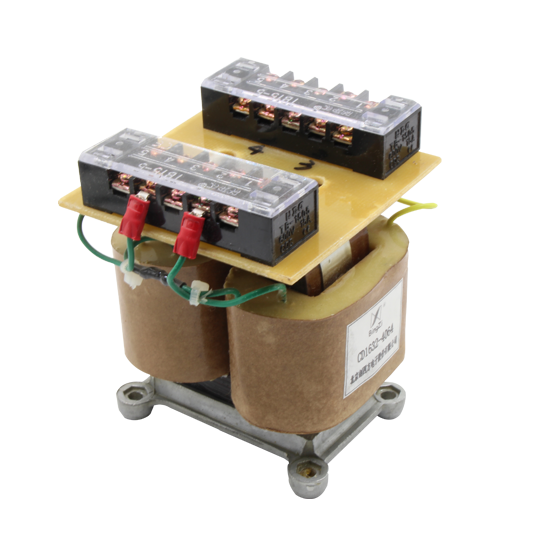

(CD-type)

①CD-type transformers are cheaper than R-type transformers, and have better electromagnetic properties than EI-type transformers; ②CD-type transformers have been standardized in my country as early as the end of the 1960s, so this type of transformer has good versatility and interchangeability. Also because of this, for users with a small amount of transformers, when using this type of transformer first, the capital investment is small and the effect is quick; ③CD-type transformers generally adopt the form of double-wire package (double is also called core-type transformer). Its stray magnetic field can be canceled, the magnetic interference is small, and the coil heat dissipation surface is large. It is suitable for processing medium and high-power transformers.

(EI Type)

①The iron core adopts the international series standard iron core specifications ; ②The iron core is punched by a large professional processing factory. Iron core material, stamping quality and supply are guaranteed ; ③Production tooling can be in line with international standards , suitable for mass production; ④The structural changes are diversified and the product prices are low .

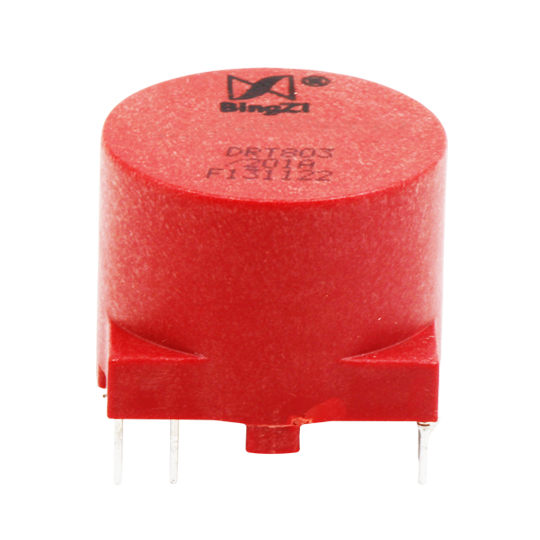

(DRT Series)

The DRT Series IGBT drive transformer is the latest product developed by our company for driving IGBTs and MOSFETs. It uses new materials as the magnetic core and can meet multiple application requirements.

These two series of products are high withstand voltage drive transformers. They have the characteristics of a compact structure, and their most notable feature is their extremely high electric strength. In addition, DRT810 series products have two spare input channels on the primary side. Each channel is connected with a diode, and the secondary side has a built-in shaping circuit. When in use, a diode can be connected in series with the thyristor gate to prevent negative polarity gate pole current. Additionally, if you want to measure the thyristor gate current, you can connect a measuring resistor to the secondary side and use the secondary output point as the measuring point to measure the voltage across the resistor, which allows you to determine the magnitude of the gate current.

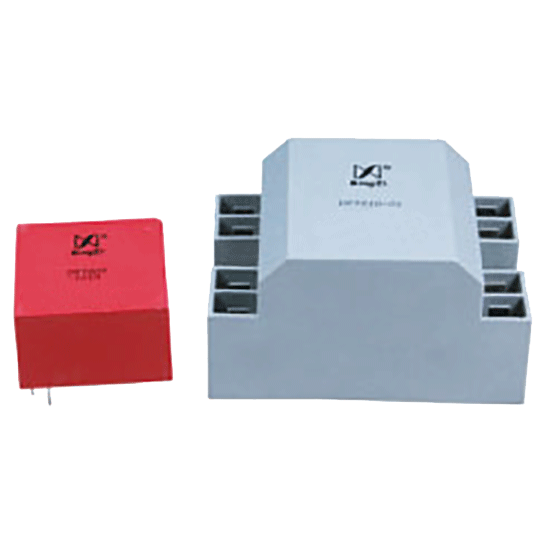

(KCB Series)

① The printed circuit board is totally-encapsulated, allowing for direct welding and assembly. ② It has a high capability of mechanical and environmental isolation, is compact in structure, solid, vibration-proof, moisture-proof, and flame-resistant. ③ It has high dielectric strength between coils. ④ The ratio can be changed by customers to meet the requirement for triggering. ⑤ It is able to match thyristors of all capacities. ⑥ It is able to be used as common pulse transformers.